Quality

Full control

CARCANO quality is the result of comprehensive and rigorous controls at every stage: from design to prototyping, from the choice of raw materials to processing and from the finishes and laboratory testing to storage.

MATERIALS

DESIGN

PROCESSING

PRODUCTION

LABORATORY

TRACEABILITY

AUTOMATION

Ma

ter

ials

Raw materials with certified top quality

The raw materials used for the manufacture of our products are selected right from the start on the basis of strict certification that confirms their quality: among other elements, they need to show high resistance to failure strain and must not contain any particular impurities or inclusions.

De

sign

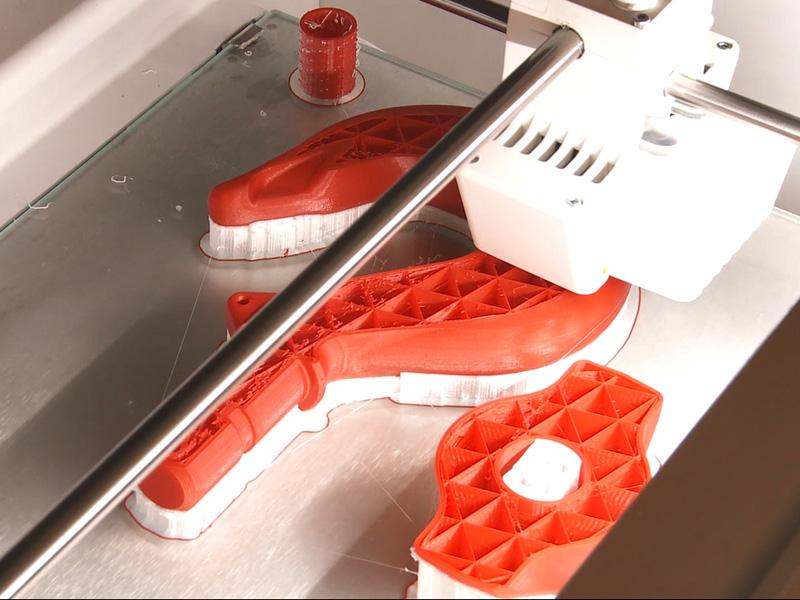

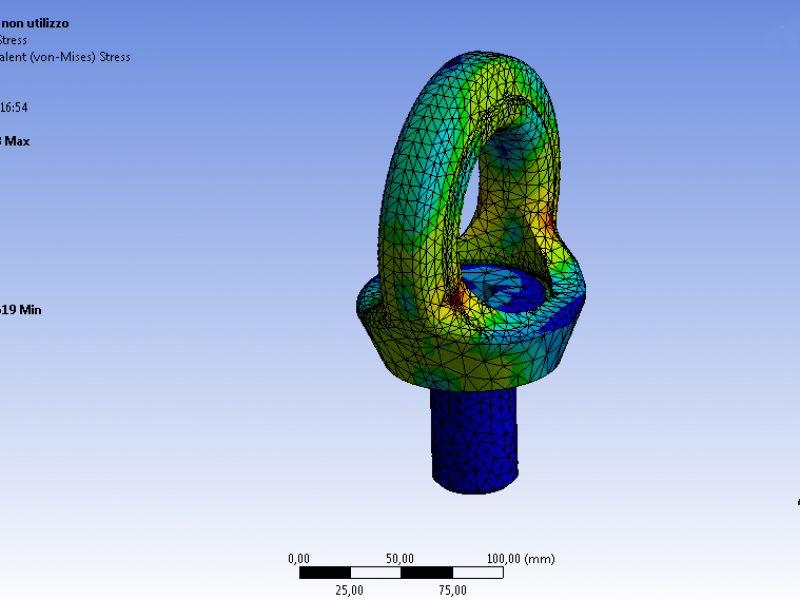

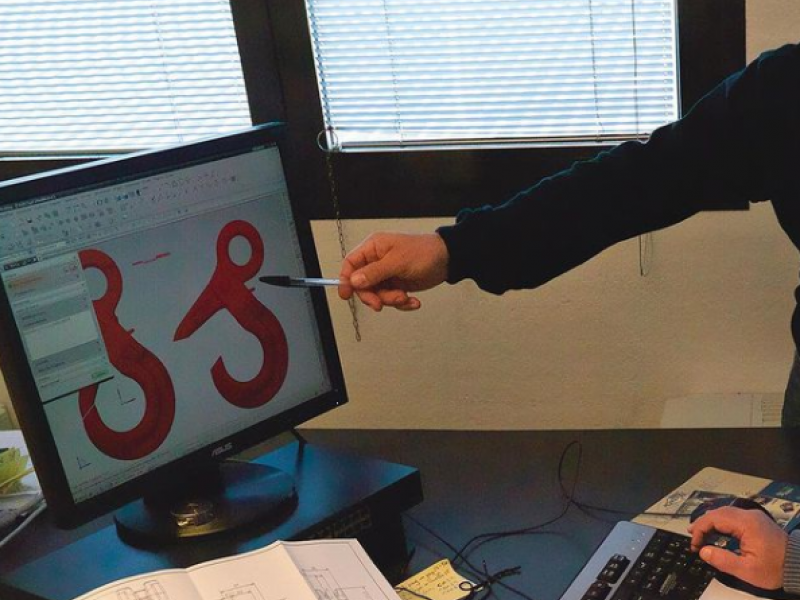

Qualified personnel and high technology

A team of engineers and specialist technicians with many years’ experience in the industry have at their disposal the most modern and sophisticated technological instruments for design work and in-house preparation of test prototypes of new pieces before going into production.

Pro

ces

sing

Direct management over the whole process

CARCANO performs in-house all the processing and machining required to manufacture its lifting systems: from the initial dies to the actual production, from the tests to storage and shipping operations; every phase is managed internally so as to ensure quality, control and flexibility.

Pro

duc

tion

Forging: hot forging processes

Over fifty years’ experience and innovation have made forging one of CARCANO’s leading quality successes. The process parameters are constantly monitored and modern analytical software allows our excellent quality standards to enjoy ongoing optimisation.

Lab

orat

ory

Quality control and laboratory testing

A cutting-edge testing facility, equipped with all the best and latest technologies, provides evidence of our determination to pursue, improve and define a new concept of total quality. The CARCANO laboratory performs traction tests, spectrometric analyses and X-rays, resilience and fatigue testing, magnetic particle inspections and other checks.

Tra

cea

bility

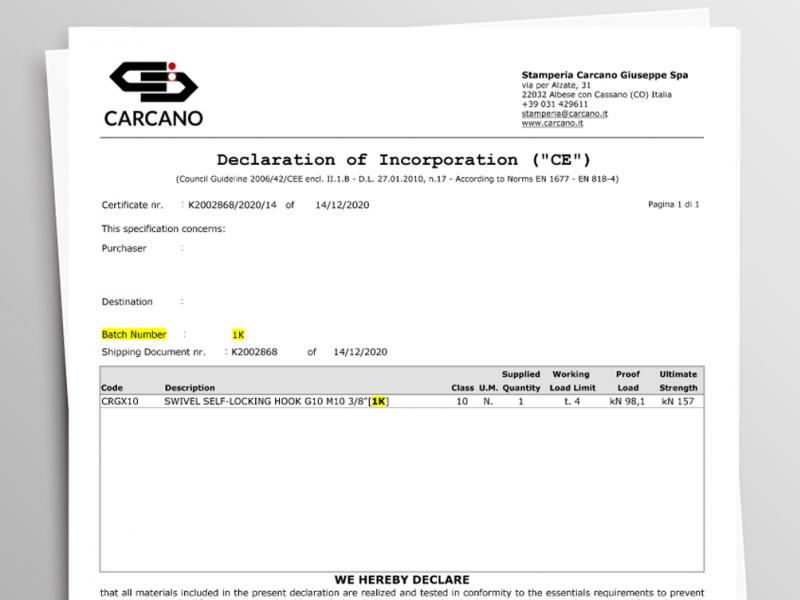

The tracking chain

Full tracking of lifting systems enables us to look back at every stage in the history of each part: from an individual casting to all subsequent processes, including all the quality controls conducted throughout production.

Auto

mat

ion

Automated warehouse for storage and picking

Our products are stored in a modern and well-equipped, automated warehouse which has a customised picking and storage system. This department is outstanding in its efficiency, effective use of space and performance, optimising and ensuring delivery times.

Our certifications

CARCANO uses a set of certifications for its processes and products so that we can assure our customers that maximum performance is our byword at every stage. Any other certificate is provided on request.

Read our magazine

The world of lifting systems and devices for personal protection and safety is a world that is always developing: here’s our contribution to keep you up-to-date at all times.

READ IT HERE